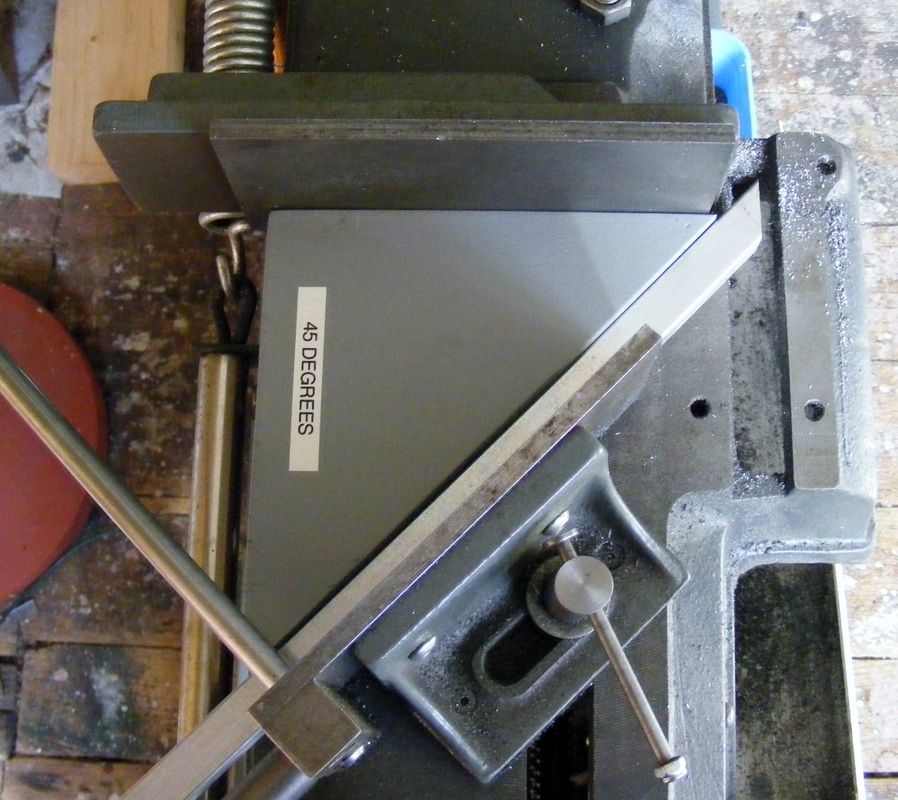

Angle cutting on the bandsaw.

When fabricating frames and stands certain angles are required often. The most common requirement is for 90 degree and 45 degree angle cuts. It is time consuming to keep switching from 90 degree to 45 degree cuts by swivelling the fixed jaw. If only a limited number of angles is required it is much easier to make angled blocks of wood corresponding to the different angles. This eliminates having to reset the vice each time the angle is changed.

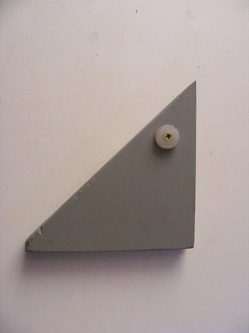

The block was cut from 25 mm planed timber to the required angle.

The plastic disc fits into the slot that the moving jaw slides in. This prevents any sideways movement of the block as the vice is tightened.