Drilling machine hold down.

I saw a photograph of a hold down similar to this one in a magazine. I do not know if this type of clamp is commercially available but I have not seen one in UK tool supplier catalogues. It seemed such a simple and easy way to clamp work to the drilling machine table that I decided to try and make one.

I had an old 7" visegrip wrench where the jaws were a bit loose and wobbly due to wear on the pivots. This was similar to the wrench in this photo.

The rivets that hold the jaws into the visegrip were centre punched, the heads drilled away and then they were punched out.

The rivets that hold the jaws into the visegrip were centre punched, the heads drilled away and then they were punched out.

The photo above shows the components of the hold down. The two handles from the visegrip are on the left. The roughly triangular shaped piece with the spring attached is a new piece and it has a swiveling clamp piece attached to the right hand side. Below the bottom handle are the components that clamp the hold down to the drilling machine table. To the left of the clamping components are the pivots that hold the parts together when assembled.

A 6mm hole is drilled 12.5mm in from the end of the bottom handle.

This is the M6 screw that clamps the hold down to the drilling machine table.

The head has been cut away on two opposite faces of the hexagon head so that it is the same thickness as the threaded part of the screw. The screw will then fit between the two sides of the bottom handle.

The head has been cut away on two opposite faces of the hexagon head so that it is the same thickness as the threaded part of the screw. The screw will then fit between the two sides of the bottom handle.

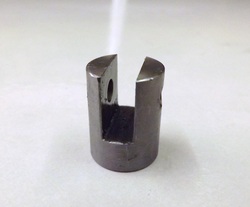

The bottom handle fits into this saddle piece. This was made from a 20 mm length of 25 mm round steel. This was faced both ends and drilled through with a 6 mm hole. It was then cross drilled with an 10 mm drill and cut in half forming the saddle.

The saddle is secured to the handle with the screw and a special circular nut. The nut is 16 mm diameter, 4 mm thick and threaded M6.

The circular nut fits into the slots of the drilling machine table.

The circular nut fits into the slots of the drilling machine table.

The screw passes through the handle and the saddle. The circular nut tightens hard down on to the saddle. This was done by gripping the nut in a vice and rotating the handle to tighten it.

The roughly triangular piece was cut out from 6 mm thick steel. The spring was attached through a 2 mm hole. Metal was milled away to a depth of 1 mm around the hole so that the spring hook was recessed. The other holes were drilled 5 mm.

The clamping nose was made from apiece of 16 mm round steel. This was cross drilled with a 5 mm hole for the pivot and then the piece was slotted with a 6 mm slot drill.

The pivots were made from 5 mm round steel. This was drilled 2.5 mm and then tapped M3. The pivots were held in place using M3 washer and screws.

The hold down was then assembled using the the pivots.

The clamp screw has a piece of 12 mm square steel drilled through with a 6.5 mm hole as a washer and a nut with tommy bar as shown. This nut and washer will pass through the slots in the drilling machine table. It s only necessary to put the nut and washer through the slot, twist the washer at right angles to the slot and then tighten the nut to securely fix the hold down to the drilling machine table.

The clamp screw has a piece of 12 mm square steel drilled through with a 6.5 mm hole as a washer and a nut with tommy bar as shown. This nut and washer will pass through the slots in the drilling machine table. It s only necessary to put the nut and washer through the slot, twist the washer at right angles to the slot and then tighten the nut to securely fix the hold down to the drilling machine table.